Surface Testing

Stain tests. Solvent tests. Scratch tests. Tests and more tests. We test and then test some more. You’ll be glad we do.

Why is Testing So Important, and Which Tests Were Conducted?

Can one test too much? We don’t think so. To ensure that Azdel Onboard composite sheets can withstand the elements, whether outside a unit or in, we are constantly testing. And to ensure that our DuraBlend™ interior finish was up to the task of competing with, or even surpassing a typical vinyl décor material in terms of durability, we had our material tested by a third party specialist. The Stain and Solvent Resistance test is used to determine a surface material’s resistance to a variety of common and potentially destructive agents – in this case:

| Water | Ketchup | Citric Acid | Acetone | Wax Crayon |

| Tea | Mustard | 50% Ethyl Alcohol | Ammonia | Sharpie Marker |

| Coffee | Red Wine | Vegetable Oil | #2 Pencil | Black Shoe Polish |

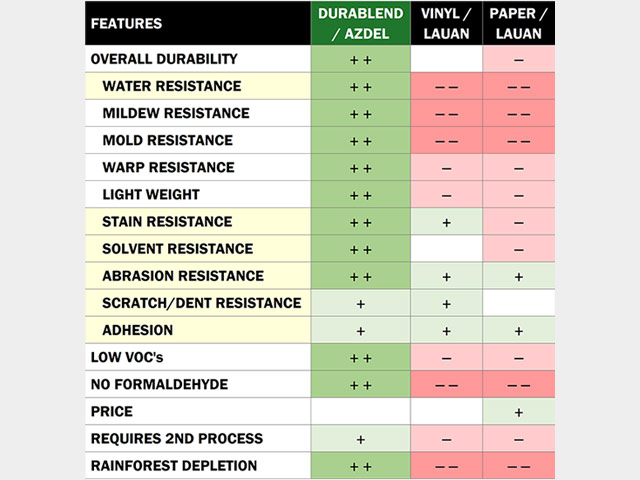

Durability Test Results and More

These substances were applied to and left on samples for durations of 1 hour, 2 hours, 4 hours and 16 hours. The effect of each substance was then determined at each interval, with ratings for each ranging from 0-no effect, to 1-moderate effect, to 2 severe effect. Thus, the lower the number, the better the resistance.

The Azdel DuraBlend interior sample was compared to two other interior samples, a paper laminate on lauan plywood and vinyl laminate on lauan plywood, each undergoing the same test. The individual results were then averaged, yielding an overall value. The lower the average, the more resistant to these agents a material is.

While they were at it, similar samples were also subjected to Taber Abrasion testing, Hoffman Scratch and Mar testing, and MEK (methyl ethyl ketone) Rub testing.

The results of these tests, as well as other features of interior panel options, are reflected in this comparison matrix. Because each test method is different, and each standard of measure is different, we needed a streamlined way to assign a value for different results.