Temperature & Humidity Resistance

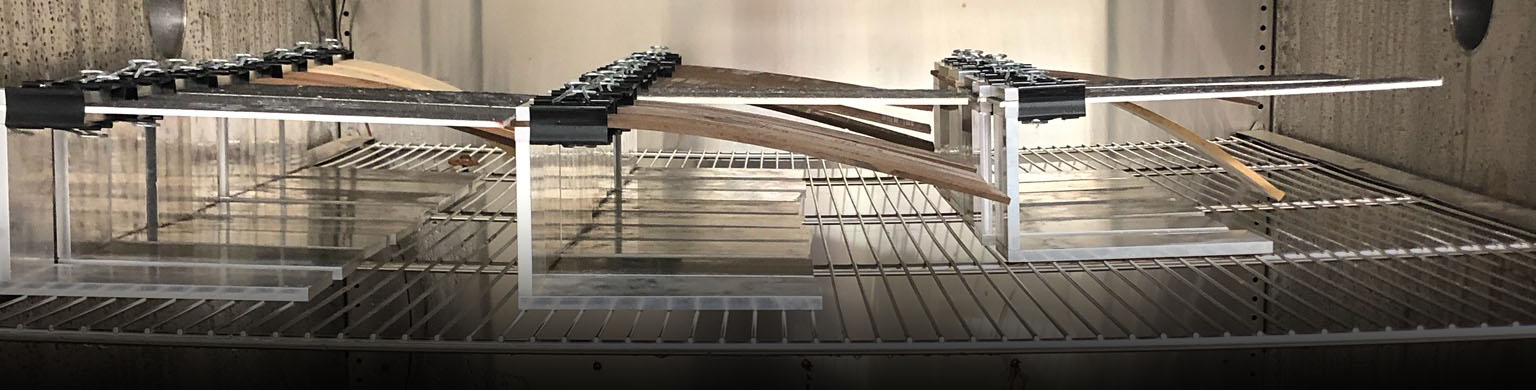

This is a Cantilevered Sag Test with various materials, including wood and fiberboard. The samples with white edges are Azdel.

While other samples sagged easily between 20mm and 103mm from humidity, the maximum Azdel dip was a mere 2.4mm!

Thermal Expansion

Regardless of where you live, your RV travels and is set up outdoors. Even if your Humidity stays low, your Temperature may not… and it all matters!

Given enough temperature increase, nearly all materials will expand. Conversely, as temperature drops, nearly every material will contract. The amount of expansion or contraction a material undergoes depends on both the material type and the change in temperature. While these changes in material can occur in multiple directions – and there are other mathematical formulas to account for this – we are focused here on the change in length. For this we look at the Coefficient of Linear Thermal Expansion (CLTE).

In simple terms, CLTE establishes a value of percent change per unit dimension of material in response to a change in the material’s temperature.

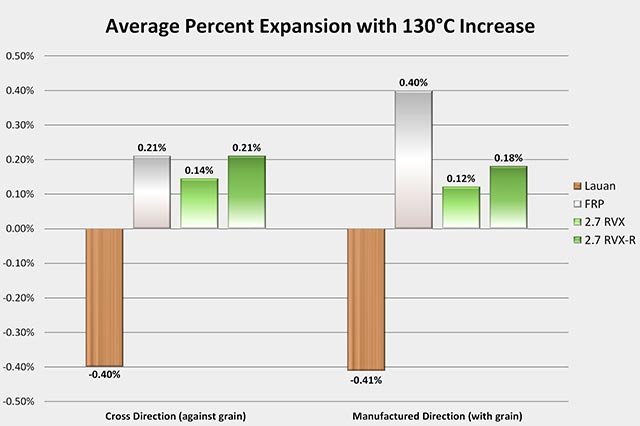

Without calculating the true CLTE, we can still compare the percent of expansion (or contraction) of a sample with a given temperature change. A specialized testing company using controlled conditions measured the change of four sample types: lauan, FRP*, Azdel RVX and Azdel RVX-R (EcoLite). Tested were three pieces of each 2×12″ sample type. The average was determined after each was subjected to a 130°C increase for 24-hours. See the graph below for results. *FRP is Fiber(glass) Reinforced Polymer, the outer skin of most laminated RVs.

Thermal Expansion Graphed

Of the four material types, the Azdel composite samples experienced less change with regard to their linear dimensions. It is also evident that FRP, the outer skin on most laminated RV sidewalls, is much more aligned with the expansion properties of our composites, than it is with lauan.

Perhaps the most eye-opening aspect of this test was learning just how far in the opposite direction the lauan samples changed. As the temperature increased, FRP expanded but lauan contracted. As the temperature decreased, FRP contracted and lauan expanded. Why? Even in its “dry” state, water still makes up about 10-15% of wood’s total mass. And unlike these and other construction materials, water expands when it freezes. Even as a fraction of its make-up, the water’s reaction is powerful enough to force the wood to expand. The result: no matter which direction the temperature fluctuates, lauan is continuously fighting with the FRP to move in the opposite direction, initiating and speeding up the delamination process.

Thermal Expansion in Action

This is a time-lapse video of the comparison between the expansion and contraction of Azdel composite and lauan. Both are laminated to the FRP on their respective samples.

In multiple cold and hot cycles, from -25°C to 100°C, the progressive separation of the lauan sample is clear. Its reaction is opposite of that of the FRP to which it’s laminated. As FRP contracts, lauan expands, and vice versa. This, sometimes combined with compounding factors like water ingress and mold, leads to delamination in RV sidewalls. The occasional cloudiness in the video is due to similar temperature fluctuations in ambient air moisture.

It’s important to note that both our composite and the FRP on the Azdel sample still experience movement during the same cycles, but they are working together — their movement is far more in sync, so there is much less stress on the adhesive bond. The result is a structurally sound wall that will last!