Flame and Burn Resistance

Fire is often not thought about until it’s too late. What should you know?

Flame Resistant? Flame Retardant? Burn Resistant? What Does it All Mean?

When a material is classified as Flame Resistant, that means the material itself is inherently resistant to igniting or burning, and does not melt when exposed to extreme heat. This doesn’t mean that the material is incapable of burning, but it does mean that it will not easily ignite or stay lit. It may or may not be self-extinguishing, but there is at least a measurable resistance.

A Flame Retardant material, on the other hand, has been chemically treated or enhanced to better resist burning. Might a material have had some flame resistance prior to being treated? Yes, it is possible. But it was likely determined that the application for the material required that it be more resistant than it was naturally, so it was then treated.

It is not uncommon for the phrases flame resistant or flame retardant to be replaced by the short acronym, FR. Unfortunately, FR is used interchangeably and does not specify by itself either resistant or retardant in connection with a given material. It is also common for Fire to be used instead of Flame, though most standards use the term flame.

How Does This Apply?

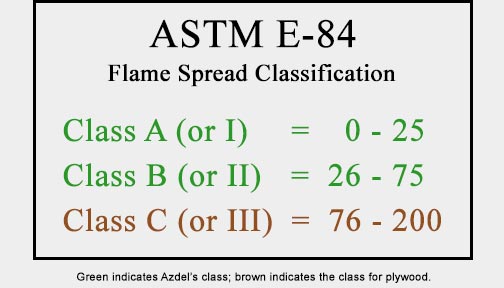

The American Society for Testing and Materials (ASTM) developed a rating of Flame Spread to compare the surface burning properties of building materials. Using their test method E-84, they measure how far and fast flames spread across a material sample. The Flame Spread Rating (FSR) or Index is expressed as a number where, the lower the number, the slower the spread. The rating usually fits into one of three Classes: I, II and III. Often used interchangeably with these are Classes A, B and C, respectively. Each class indicates a range of FSR, as shown here. We’ll explain the colors below. Here is an example of how a material’s class as fully written would appear: ASTM E-84 Class B.

An equivalent standard test method is from Underwriters Laboratories, and is known as UL 723.

While ASTM E-84 and UL 723 were developed for general construction materials, and not specifically for the RV industry, it is good that the RV industry does establish required standards.

So What is the Standard for an RV?

The National Fire Protection Agency (NFPA) has developed a specific set of standards for Recreational Vehicles, known as 1192. The small related section reads as follows:

NFPA 1192-2018 6.1.1.1 Interior finish (as defined in 3.3.35) of walls, partitions, ceilings, exterior passage doors, cabinets, habitable areas, hallways, and bath or toilet rooms, including tub/shower walls, of recreational vehicles shall be of materials with a flame spread index that does not exceed 200 when tested in accordance with ASTM E84 or ANSI/UL723.

What this standard allows for is a Class C (III) material, and a low one at that, which is, as you might expect, where wood falls on the scale at 200, shown as brown above.

Standard Azdel Onboard RVX composite panels are a step up at Class B (II). But if your application requires Class A (I) material, our FRXA is what you want. Both classes are shown in green above.

In the unfortunate event of a fire in your RV, which material would you prefer to be in there?

What About Burn Resistance?

Federal (or Canadian) Motor Vehicle Safety Standard No. 302 (FMVSS 302 / CMVSS 302) specifies the burn resistance requirements for materials used inside motor vehicles such as passenger cars, trucks, motorhomes, buses and agriculture machinery. It was developed to help reduce deaths and injuries to occupants caused by vehicle fires.

The test sample is held horizontally in a U-shaped holder and exposed to a flame for 15 seconds in a combustion chamber, in order to see if or when the flame extinguishes, or the time taken for the flame to pass a defined distance. The burning rate per minute is then calculated.

For most automotive applications, a burning rate of no more than 100 mm (3.94”) per minute is acceptable. The Azdel Onboard DuraBlend™ décor was tested at 1.85″/min.