Thermal Transmission Resistance

& R-Value

We are often asked what the R-Value is of Azdel Onboard® composite. In the past we estimated. We were wrong. It’s better!

What is R-Value?

In simple terms, R-Value is a measure of resistance to heat flow through a barrier. The barrier could be a single layer of material like an insulation batt, or multiple layers of construction material in a structured wall. The higher the value, the more resistance to heat flow a material offers, and the better insulated your unit will be. The R-value standard of thickness is one inch of material so, generally, when a figure for R-value is provided, it is assumed to be based on the standard one-inch thickness. Adding more than an inch of that material will increase the actual insulation value, and vice versa.

Thermal Transmission Resistance of Azdel Composite

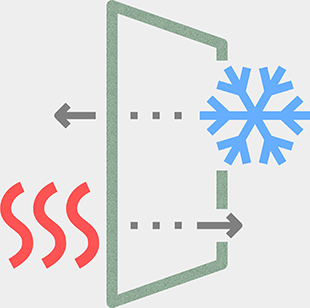

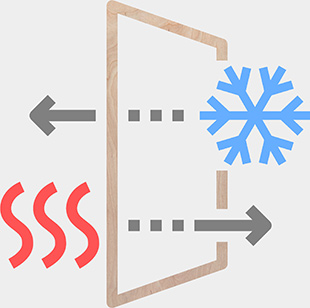

Below are depictions of the transmission of hot and cold air through different layers: Azdel composite and wood. Each layers appears as a frame to better illustrate the flow of hot and cold air. You will notice, however, that the amount passing through the Azdel composite is reduced from that of the wood sample. This is what the tests revealed, and this is what would happen in real world conditions. So then, what is the R-value of Azdel composite?

Thermal Transmission: Azdel Composite

R-value = 4.65 @ 980gsm

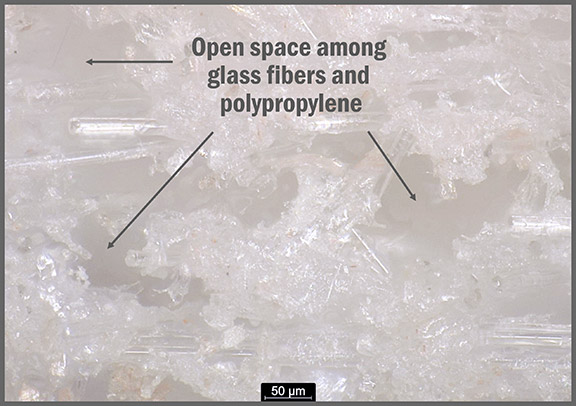

Image of Azdel composite under microscope, magnified 1,050 times.

Thermal Transmission: Lauan/Plywood

R-value = 1.0-1.2

The R-value of Azdel Onboard composite was tested to be 4.65 at a material weight of 980gsm. Typical plywood is known have an R-value of 1.0-1.2. Thus, Azdel was proven to be several times better, and even better than we previously estimated. But why?

Think of traditional fiberglass insulation batts. They are lightweight for their size, and they are porous — very porous. There is a lot of space between the fibers, and that space — the air between the fibers — serves as a virtual insulator from new air trying to pass through it. This is why our porous material performed so well.

The image above is our core magnified 1,050 times. The space between the fibers and other substances is clearly visible. You might consider these insulation pockets. This concept is not unlike the reason why our composite has such good sound absorption.