AZDEL Composite Floor

Here we dig deeper into the testing involved and reveal results compared with other materials tested similarly.

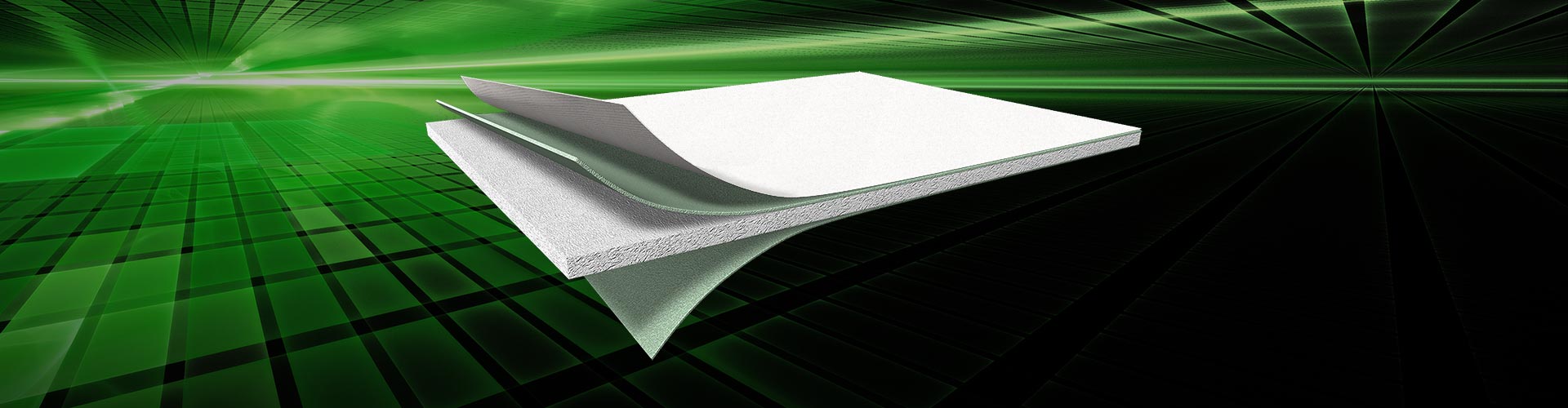

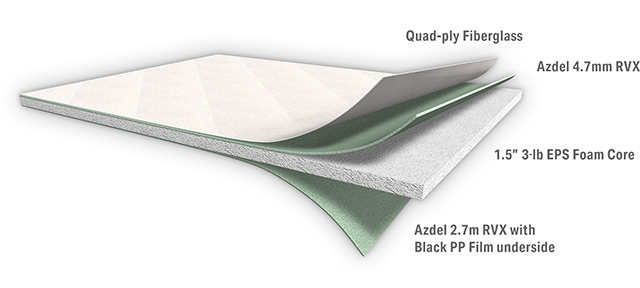

On the Recreational Vehicles page we introduced the Azdel Floor. This construction offers additional benefits such as a seamless top layer, excellent resistance to impact and flexural displacement, high strength-to-weight ratio, screw retention, and its production utilizes the same equipment, adhesives and techniques required for wall lamination.

With the exception of the marine-grade OSB, all samples tested used an EPS (expanded polystyrene) foam in their construction. This helps add rigidity, strength-to-weight benefits, and is already a commonly used material in RV construction. Read on for testing explanations and results.

While the image here depicts our recommended design for RVs that can accommodate a laminated floor, a variety of configurations are absolutely viable for RVs, trailers and other structures. Contact us for alternative suggestions. For interior floor underlayment applications, please click to our related page on Protective Barriers.

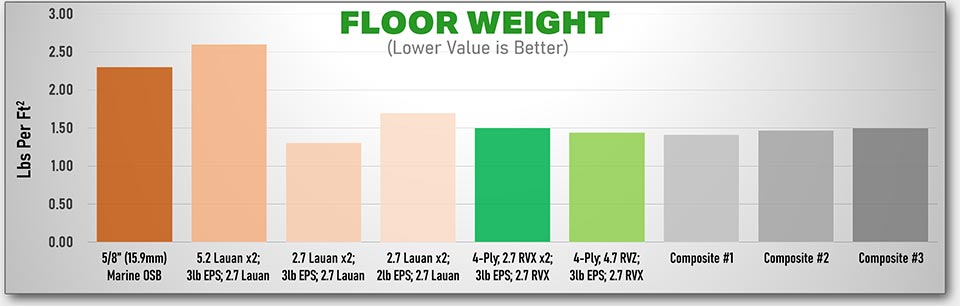

Floor Weight

This is fairly simple. As most materials in the RV industry are priced per square foot, and it’s an easy and specific measurement, this is how we compared the weights of various samples.

The significant weight difference in the two 2.7 Lauan samples illustrates how inconsistent wood can be, as the 3lb foam sample should have been heavier than its 2lb sibling, but its lauan was far less dense.

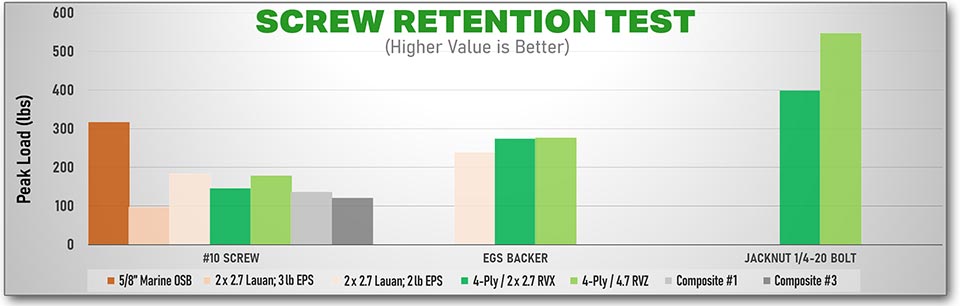

Screw Retention

While sidewalls and some other floor-mounted structures are generally bolted through the frame, having screw retention as a side benefit is still ideal. The seamless multi-ply fiberglass that we suggest for the top layer offers excellent strength in this area.

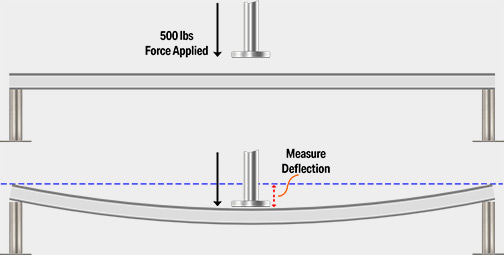

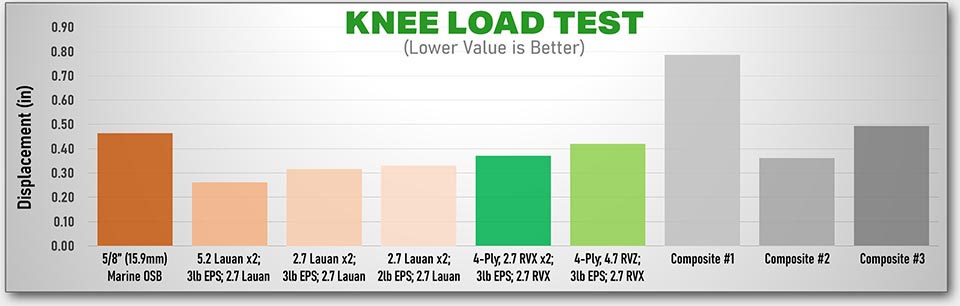

Knee Load Test

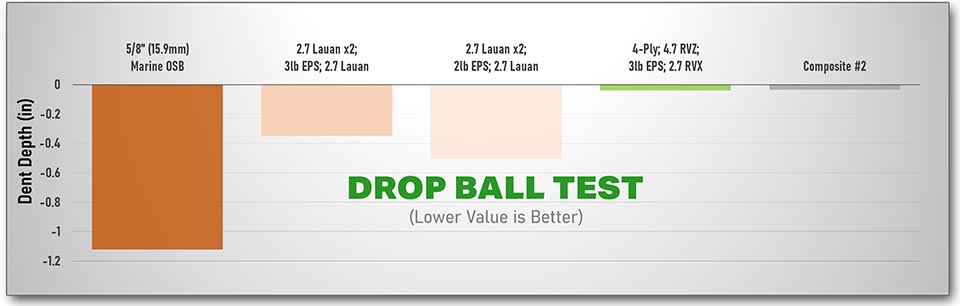

Drop Ball Test

A 4″ diameter steel ball weighing 8.1lbs was dropped from a height of 12.3ft, reaching a peak velocity of 19.2mph at impact. While this is not a common activity for RVing families, it works well in measuring impact resistance.

Do not try this at home… or in your RV… or anywhere else.

The image below is of actual samples from the test in the adjacent impact test video. There was minimal damage done to the composite samples, but significant, permanent damage to the wood samples.

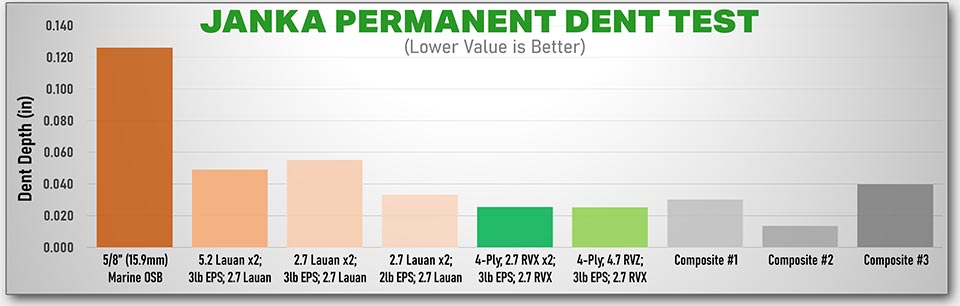

Janka Test

A standardized test in the wood floor industry, the Janka test measures the force required to push a steel ball into a wood sample distance equaling half its diameter. Since this group of materials respond to the force differently, we measured the permanent dent left by the test rather than the force.