Sun Load Testing

How well do walls made with Azdel Onboard® composite handle extreme heat?

Not All Composites Are Created Equal

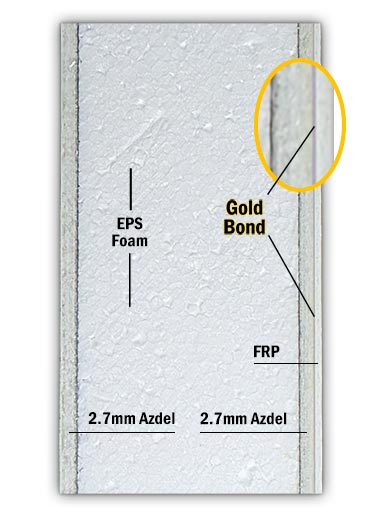

Extreme temperature fluctuations can wreak havoc on adhesive bonds, and the most critical adhesive bond in laminated walls is known as the “Gold Bond”. This connects the RV’s external fiberglass to the substrate underneath, and a poor bond often leads to delamination. To measure bond quality and prevent delamination, the RV industry has established a minimum acceptable bond line standard. Walls made with Azdel easily exceed the standard, but we wanted to check their performance after being exposed to extreme temperatures. The Sun Load test is an accelerated test designed to simulate harsh temperature ranges and cycles that an RV will likely experience over its lifetime.

The Gold Bond is the outermost glue layer between the fiberglass and its substrate, and is critical to a wall’s longevity.

Cross-section of typical sidewall

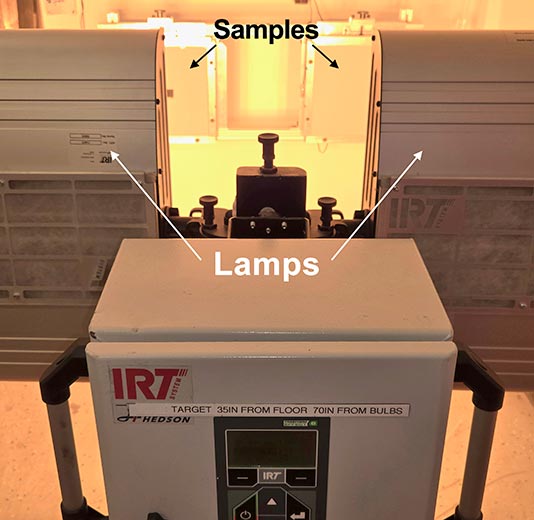

View of Sun Load Test from rear of IR lamps.

Test Details:

In the Azdel lab, an infrared lamp is used to mimic intense sunlight on an RV’s exterior wall. The temperature is cycled several times at set intervals to replicate conditions even harsher than what an RV wall would encounter in the field.

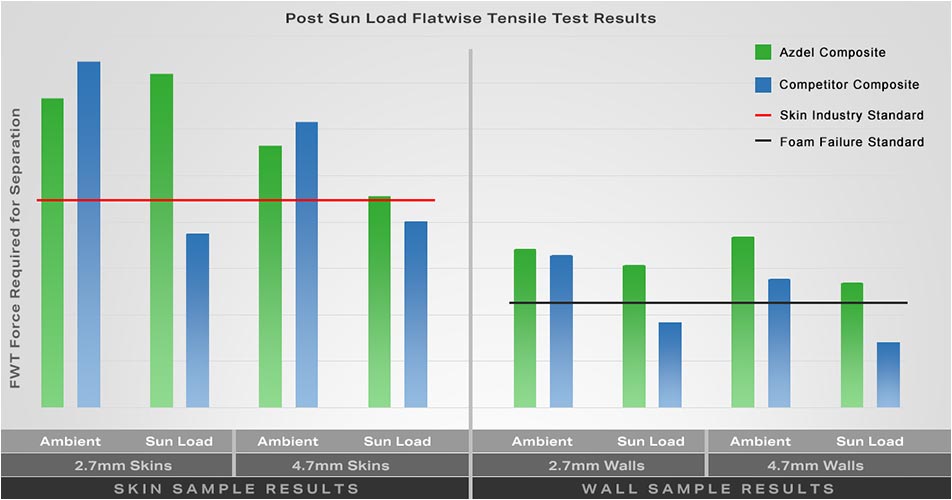

After the Sun Load test, the bond quality of the skins and walls is measured using the Flatwise Tensile (FWT) test. This ensures that the glue bond remains above the minimum industry standard even after adverse conditions.

Before delving into the FWT test, the results of the Sun Load test comparing Azdel to a competitive composite demonstrate the superior performance of Azdel. See below!

Azdel Composite Outperforms the Competition in Sun Load Test

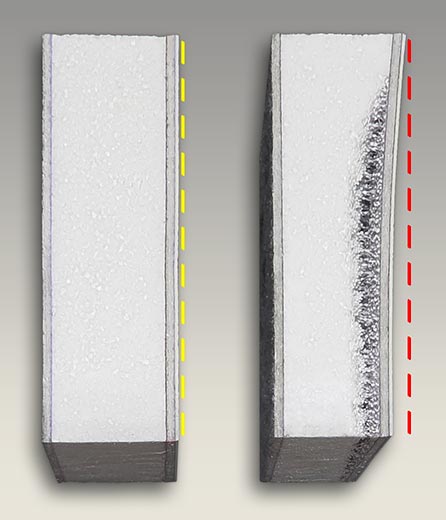

Sun Load Test: 2.7mm

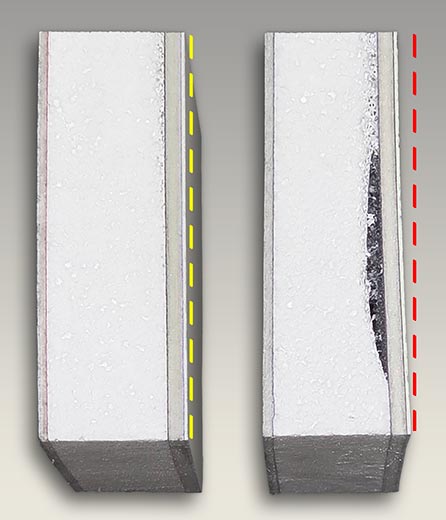

Left – Azdel Right – Competitor

Competitive Test:

One series of Sun Load tests compared the performance of Azdel composite against a competitive composite at substrate thicknesses of 2.7mm and 4.7mm. The wall construction was identical, and the tests were run simultaneously under the same conditions.

Observations:

- The EPS foam of the competitor wall sample exhibited significant melting and shrinking

- The Azdel samples’ EPS foam remained intact with minimal noticeable effects

Following the Sun Load test, the walls underwent the Flatwise Tensile test.

The real proof is in the data. See the results below!

Sun Load Test: 4.7mm

Left – Azdel Right – Competitor

Superior Azdel Performance Proven

The video and FWT test results shown below include samples tested after the Sun Load Test explained above. Skin samples and complete wall samples were tested both before and after the Sun Load test, and the force required to separate the bond line was recorded.

In each instance, Azdel’s post-test samples outperformed the competitor’s composite. These findings are consistent with the expected results of the Sun Load test and confirm that Azdel Onboard composite is the superior choice for long-lasting laminated wall performance.

The video below reveals the dramatic contrast in the performance between walls with Azdel and walls with a competing composite after prolonged exposure to high heat, much like an RV might endure in the southern sun.