Flexibility Testing

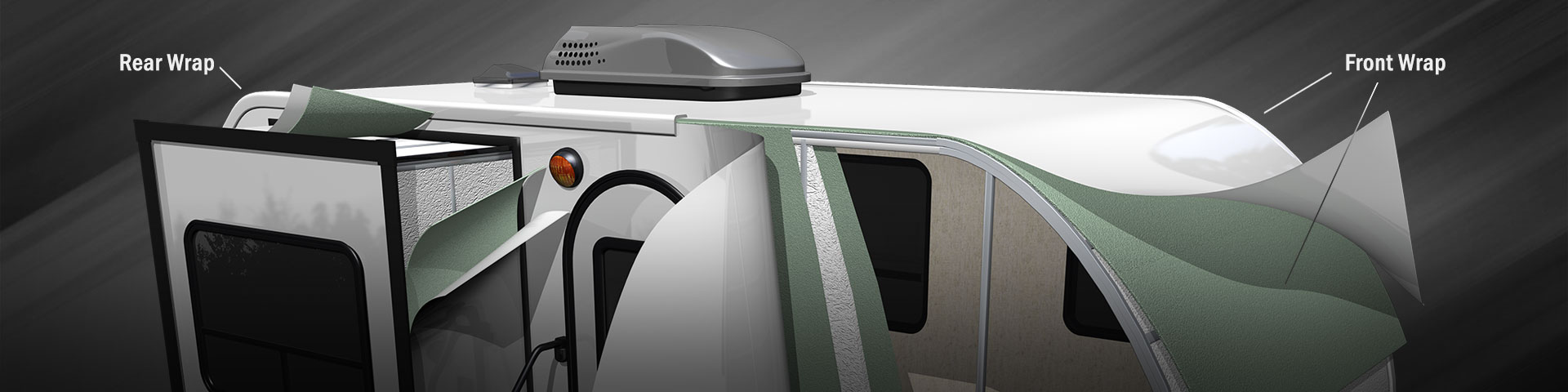

A mini travel trailer with no seam in the front-to-back roof wrap? Yes, it can be done!

Why is Flexibility Important?

There are a variety of areas on the shell of an RV that are curved. On the roof there are the front and rear corners. On a Class C, the entire nose of the cab-over can be rounded. Sometimes, as with the front of some travel trailers, that section is constructed with a molded fiberglass piece, or cap. Other times it is laminated. Even when laminated, it’s made with a different process that the mechanized methods used in constructing a typical laminated sidewall. It is often a more delicate and labor intensive process, as the exterior layers are manually formed into their proper contour. Radial torque is applied to the material to bend it into place prior to securing, but it calls for a durable material that won’t easily break.

Continue reading below, but you may also open or download our Radius Wrap Flyer with similar information.

The Test

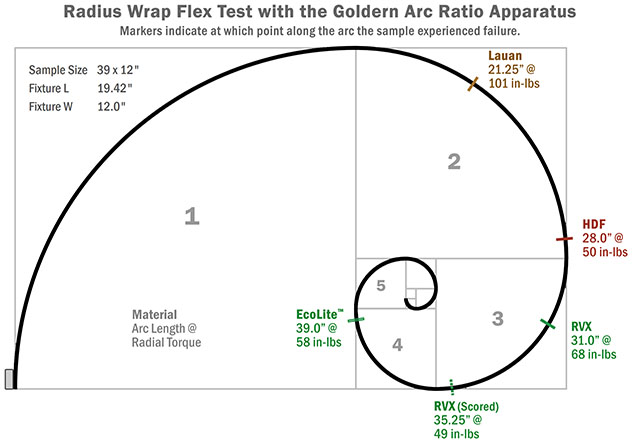

We needed to determine how flexible our products were, especially in relation to other options already in use. We also needed an apparatus that offered a natural and progressively tighter radius as the sample piece gets wrapped. The Golden Arc Ratio provided the perfect curvature for our test, and thus our apparatus was borne.

To simulate the real application, samples of 2.7mm thickness were first laminated to a layer of typical FRP. The test group included HDF, Flex Lauan (a.k.a. Bendy Board) Azdel RVX (std), Azdel RVX scored, and Azdel RVXR – also named EcoLite™. Each sample was separately affixed to the beginning point of the apparatus with a clamping block. We applied pressure to the loose end to make continuous contact with the apparatus, curving in a tighter radius by a factor of 1.618 until the sample experienced structural failure. The radius and distance achieved was then measured at that point. Each sample was tested four times in both their manufactured direction (MD) and cross direction (CD).

The Results

The label points indicate where on the apparatus each sample type scored the lowest among their four trails – where each failed soonest. The number is the distance in inches from the starting point. The average of each was slightly better, of course.

Also included in each label in the diagram is the amount of torque required to press each sample against the apparatus at that point. Lauan required the most torque by far.

While our standard RVX material significantly outperformed both lauan and HDF, it was still beaten in every way by our EcoLite. It wrapped eight inches further and required less torque. The best part? The Azdel EcoLite samples never actually failed; we simply ran out of material length for those samples.

It is clear that Azdel’s composite, especially our EcoLite version, will make radius wrap construction much easier.