Less Weight

Azdel Onboard composite is about half the weight of plywood with the same dimensions

Why Does Weight Matter?

More than ever before, and at a younger age, people are getting into RVing and the lifestyle that goes with it. RV owners want mobility, flexibility, and towability. Not everyone owns, or wants to own, a heavy duty pickup truck capable of towing a large unit. With significant weight reduction, RV’s can be towed by smaller vehicles with less towing capacity, making it easier for many to take that step into RV ownership. A lighter load, even with a motorhome, is easier on your vehicle, better for fuel efficiency and, in turn, easier on your wallet – even for those with larger trucks. And consider this: the more weight your unit consumes of your towing capacity, regardless of the vehicle you’re driving, the less weight you have available for cargo.

Every component of your RV’s construction that is wood instead of Azdel is nearly twice as heavy as it could be. Some of that weight difference gets hidden when combined with other components, as in the case of RV sidewalls. The exterior fiberglass (FRP), the foam core, and the glue that bonds it together are all parts of a laminated wall that will be there regardless which substrate is used. But excess weight in an RV should be due to extras that you pay for, or things you bring, not the basic wall construction.

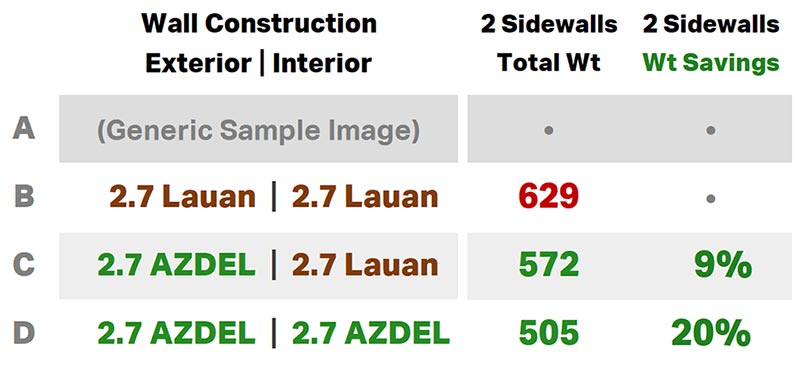

Sidewall Weight Comparison – Travel Trailers

The matrix below compares the weights of sidewall construction types for an average travel trailer. It also reveals the weight savings that can be had by using Azdel instead of wood. The sample images below the matrix are of cutouts from real travel trailer sidewalls. These all use 2.7mm layers for the exterior side behind the FRP, which is typical of most travel trailers. Some brands use 3.6mm, but we have not included such weights or images here.

28′ Travel Trailer

This comparison assumes the following:

- All weights are in pounds (lbs.)

- Indicated layer thicknesses are in millimeters (mm)

- Other wall layers – FRP; foam core; décor – are identical

- Travel Trailer walls use seven 4×7′ sheets; 392 sq ft

- The appropriate weight of adhesive is included

- Lauan is dry*

*Dry lauan still contains 10-12% water content.

This can fluctuate, leading to inconsistencies in the wood.

1.61 lb / sq ft

1.46 lbs / sq ft

1.29 lbs / sq ft

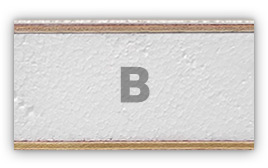

Sidewall Weight Comparison – Fifth Wheels

The matrix below compares the weights of sidewall construction types for a large fifth wheel. It also reveals the weight savings that can be had by using Azdel instead of wood. The sample images below the matrix are of cutouts from real fifth wheel sidewalls. Walls of fifth wheels often include thicker layers, particularly on the exterior side. Shown below is a double layer of 2.7mm lauan and its common upgrade, a 4.7mm layer of Azdel composite.

40′ Fifth Wheel

This comparison assumes the following:

- All weights are in pounds (lbs.)

- Indicated layer thicknesses are in millimeters (mm)

- Other wall layers – FRP; foam core; décor – are identical

- Fifth Wheel walls use ten 4×9′ sheets; 720 sq ft

- The appropriate weight of adhesive is included

- Lauan is dry*

*Dry lauan still contains 10-12% water content.

2.00 lbs / sq ft

1.60 lbs / sq ft

1.58 lbs / sq ft

1.43 lbs / sq ft

Floor Construction and Weight

Floor construction may be an afterthought for many RV buyers. They may decide between a motorhome and towable, or between a travel trailer and a fifth wheel. Then they may look for a unit with Azdel in its wall construction — always a wise step. But how often are the floors asked about? “Is it made of wood? If my RV leaks will water end up on, and maybe IN, my floor eventually? If my floor rots, what will it take to replace it?” Sadly, these are valid questions. But what if they didn’t have to be? Having a floor constructed with Azdel composite instead of wood virtually assures that your floor will never rot, even if your unit somehow leaks. As an added bonus, your Azdel floor will likely be lighter and possibly sturdier.

Our recommended constructions will use a multi-ply fiberglass for the top surface, which most floor finishes, such as vinyl, will adhere well to. The fiberglass is a seamless layer that comes in a roll, much like FRP does for wall construction. This continuous strand fiber offers excellent screw retention, impact resistance and, when combined with other layers, great rigidity. Depending on floor requirements, this fiberglass can be made available in a 4-ply, 3-ply and 2-ply version, and it may come in a translucent white or black color.

We use a black polypropylene film for the underside. It is an ultra-lightweight, waterproof and cost-effective alternative to common underbelly materials used today. We are happy to assist manufacturers in developing floor constructions that are perfect for each unit. Below are images of various construction types as well as two comparative matrices. Don’t forget to check out our main Flooring page, where more information will soon be added.

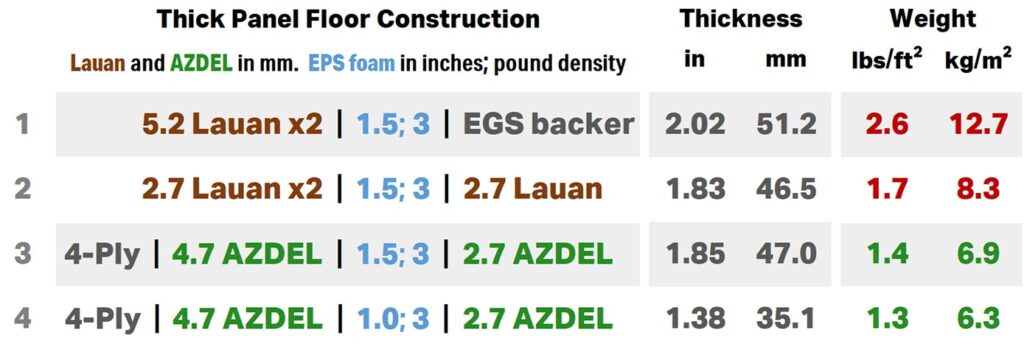

THICK Panel Subflooring

One popular construction in the industry included two layers of lauan on the top. Often those layers are 2.7mm each; sometimes they are 5.2mm each. Either way, this adds unneeded weight to your unit — weight that could be used for things you wish to add or bring, or perhaps weight you’d like to save to lighten your load.

When combined with other layers, such as multi-ply fiberglass and foam, an Azdel-constructed floor offers a durable, long-term alternative to wood subflooring. Impact resistance, stiffness and waterproofing are all enhanced benefits that become standard with our recommended configurations.

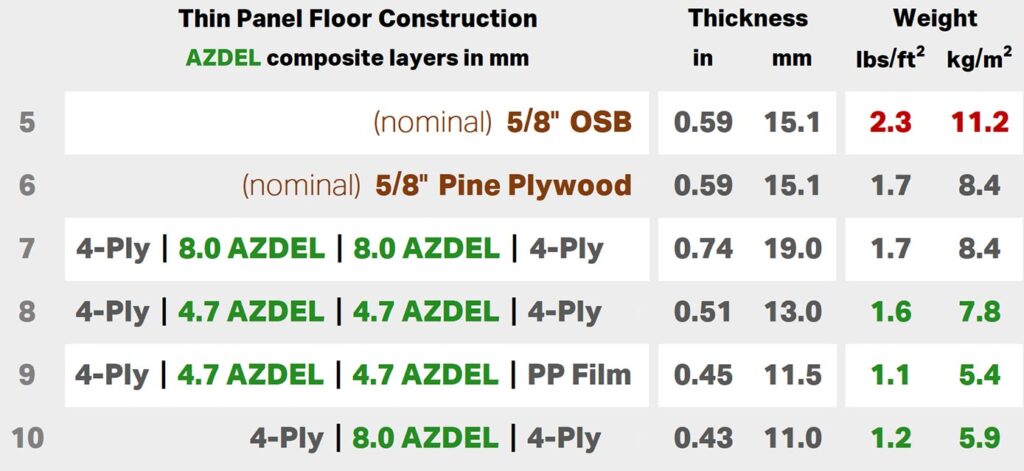

THIN Panel Subflooring

Most smaller travel trailers, minis and teardrops will have a thinner floor than a typical larger unit. As such, we needed to find a way to more closely match the thickness so that manufacturers are not forced to redesign their interior to accommodate a better floor.

Wood floors that are 5/8″ and 3/4″ are fairly common. Here we have compared ours with 5/8″ wood floors, but a 3/4″ wood floor would be about 20% heavier than what is indicated here.

These thinner solutions, all under an inch, are great alternatives to thinner wood subfloors. Like the thick versions, these still offer impact resistance, stiffness and waterproofing.