Environmental Testing

How to determine if a laminated wall will hold up year after year in harsh and changing environments

The Environmental Test

RV walls, floors, and roofs are designed to last for the lifetime of the units. Ensuring the integrity of the bonded layers during manufacturing is crucial. Azdel takes this one step further by ensuring the glue bonds maintain their integrity throughout the life of the unit through accelerated Environmental Testing.

Environmental Testing exposes materials to extreme variations in heat, cold, humidity, and dryness over a short period. Similar to the Sun Load Test, this procedure stresses the bonds between materials beyond what they would encounter under normal conditions.

Following environmental testing, Azdel conducts the Flatwise Tensile test to confirm that the bonds between layers remain strong, even after enduring extreme conditions.

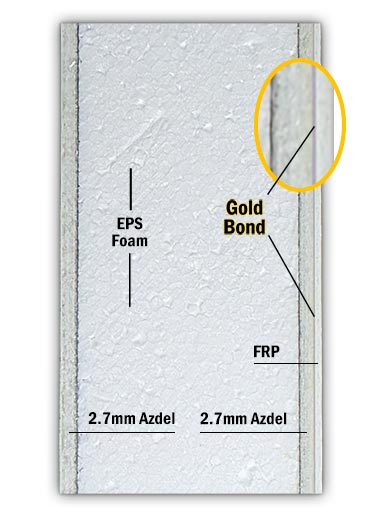

The Gold Bond is the outermost glue layer between the fiberglass and its substrate, and is critical to a wall’s longevity.

Cross-section of typical sidewall

Environmental Test Setup

In the sealed chamber shown here, laminated samples are subjected to rapid, repeating cycles of atmospheric conditions, ranging from extreme heat, cold, humidity, and dryness.

At the completion of this test, we note any visible changes to the samples, which we’ll observe below. However, the Flatwise Tensile test reveals what we can’t see: the effect on the samples’ bond lines after the Environmental test.

See the results of the Environmental test below.

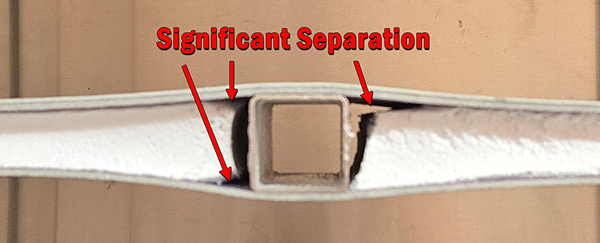

Azdel Appears Ahead in Post-Test Observations

In the Azdel sample, both the gold bond and foam bond remain intact, with no visible separation between the FRP, substrate, or foam. This demonstrates to Azdel what consumers can expect throughout the life of the unit.

In the competitor’s sample, while the gold bond appears to have remained intact, the foam bond showed significant separation between the substrate and foam, weakening the wall and reducing overall performance.

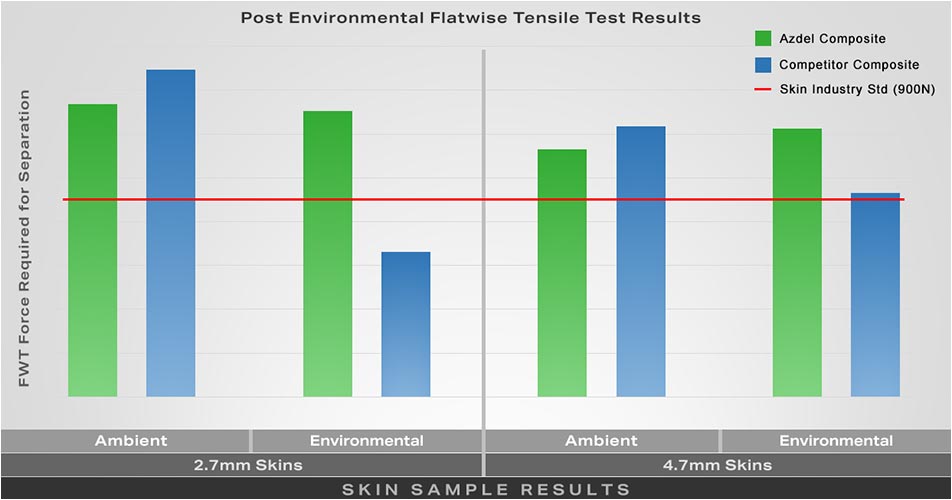

Azdel is Still Superior

To complete the process and confirm that the gold bond remains intact and strong, we conduct the Flatwise Tensile Test. We welcome you to visit the Flatwise Tensile Test to learn more. In the meantime, the test results graphed below reflect and validate the superior performance of Azdel composite and its adhesive bonds versus those of a competitor.

Azdel Excels in Environmental Test

The series of skin samples of two thicknesses were tested before and after the Environmental test, and the force required to separate the gold bond line was recorded.

Both series of Azdel’s post-test samples outperformed the competitor’s composite. In one series the competitor’s composite failed to meet the industry standard for the gold bond. In the other, it barely passed.

These findings are consistent with the expected results. This confirms that Azdel Onboard composite is the superior choice for long-lasting laminated wall performance.