DIY Care & Repair

Motorhome remodel? Check. Wall repair after a water leak and wood rot? Check. Annual maintenance? Check.

Want to Do It Yourself?

Besides repair questions, we are often asked about cleaning or waxing procedures for RV wall exteriors. More specifically, how to take care of Azdel. This is a good time to clarify where in a wall Azdel Onboard composite can be found.

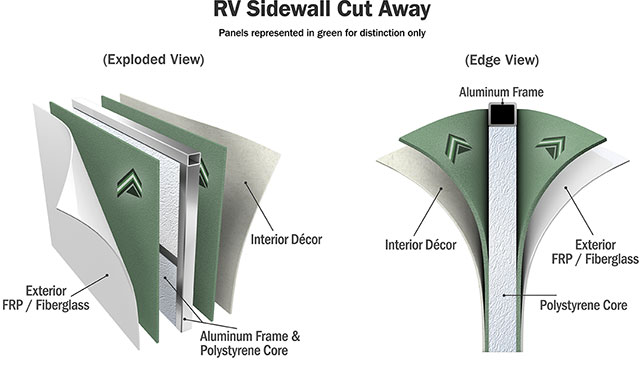

The graphics to the right represent, from different angles, a typical laminated sidewall that includes our composite. Our material is not always on both sides, but it is ideal for maximum weight savings and optimal protection against water damage.

In all cases, the exterior skin that you can see and touch, and that gets washed, waxed and sealed, is a layer of Fiber(glass) Reinforced Polymer or FRP. Our material is glued to and sandwiched between this layer and the frame and foam core. Among other things, the Azdel Onboard composite adds structural support. You won’t see our material on your RV, but you will enjoy the benefits for years to come!

Automated Adhesive Application

Here is one of two common methods of applying adhesive to the individual layers of a wall during lamination. The other is a roll coater. Glue was first applied to the FRP and our sheets were then laid on top. Both layers are seen here as glue is applied to the composite surface. The frame and foam will then be laid onto the glue. Both mechanized processes take very little time per wall once underway.

A manual job is neither as fast, nor as easy, especially if a wall is already installed, as on a finished unit. The “how-to” will be covered further below, and a link is included, but first we’ll share some tips.

Helpful Tips

What to Avoid:

- Adhesives or solvents that melt the EPS insulation (often called Styrofoam)

- Latex or other water-based adhesives requiring water evaporation to “dry” the adhesive

What to Look For:

- If the glue label indicates “recommended for lamination of two non-porous surfaces” then it will probably work.

- Some adhesives are more solvent-based, but still intended for FRP (don’t use on the foam side). The open time of solvent-based adhesives are often affected by the ambient temperature and/or humidity.

- If the adhesive has a very low viscosity you may need to apply multiple coats to ensure the glue stays on the surface to transfer sufficiently to the other material. Apply this glue to the black side of the AZDEL Onboard® composite, which resists penetration.

- If the adhesive has a high viscosity, care must be taken to ensure some of the glue passes through the surface fabric and bonds with the core of the composite sheet. This can generally be achieved by applying the glue with a trowel and a little pressure. Apply this glue to the white side, which allows more penetration.

- Ideal penetration into either side, for a mechanical bond, is 0.1-0.3mm.

Maintenance and Repair

Because not all RV’s are built the same and, not all repairs require the same materials or scope of work, we hesitate to recommend any one method, any one glue, etc. Most RV repair shops have the tools and know-how to get the job done. We are learning that more shops are adopting Azdel Onboard composite sheets as their go-to material for repairs, even when lauan was in the original construction. They say it’s easier to work with and they know rotting and warping will never be a problem, at least in the repaired area.

One wall manufacturer was good enough to provide information for maintenance and repair tips and techniques. You may access their library of information here: CC RV Care.